Saset Horizontal Milk Cooling Tanks

Product Overview

Saset horizontal milk cooling tanks represent the pinnacle of dairy refrigeration technology for large-scale milk producers, processors, and cooperative collection centers across Kenya. Engineered specifically for high-volume operations that demand reliability, efficiency, and exceptional milk quality preservation, these professional-grade chillers combine robust construction with intelligent automation to deliver outstanding performance day after day.

Experience superior milk preservation with Saset’s premium horizontal milk cooling tanks, engineered for high-capacity dairy operations. These advanced milk chillers feature:

- AISI 304 stainless steel construction,

- Laser-welded evaporators for optimal heat transfer, and

- 60mm HCFC-free polyurethane insulation for maximum energy efficiency.

Equipped with direct expansion cooling technology that chills milk from 38°C to 4°C in under 3 hours, automated CIP cleaning systems, digital level indicators with ±0.2% accuracy, and user-friendly touch screen controls. The zero-residue drainage design, 28 RPM agitator system, and scroll compressor ensure consistent milk quality while the IP65-rated electrical components guarantee reliable operation in demanding dairy environments.

Saset Horizontal Milk Cooling Tanks

Premium Construction Quality

- Stainless Steel Excellence

Every Saset horizontal milk cooling tank is manufactured entirely from food-grade AISI 304 stainless steel, the industry standard for dairy equipment due to its superior corrosion resistance, hygienic properties, and durability. The inner tank walls feature 2mm thick stainless steel construction that provides structural integrity while maintaining optimal heat transfer characteristics.

The innovative design incorporates a 0.8mm laser-welded evaporator coupling directly bonded to the inner surface, creating an exceptionally efficient cooling interface. This precision laser welding eliminates gaps and ensures uniform heat distribution across the entire milk contact surface. The outer tank shell features 1.5mm stainless steel construction, providing additional strength and protection.

- Professional Finishing

All welded joints are executed using Argon TIG welding technology, producing first-class smooth welds that meet pharmaceutical-grade cleanliness standards. These perfectly polished welds eliminate crevices where bacteria could harbor, ensuring the highest levels of milk hygiene. The smooth inner surfaces with rounded angles facilitate thorough cleaning and prevent milk residue accumulation.

- Advanced Insulation Technology

The 60mm insulation gap between the inner and outer tanks is filled with water-based, HCFC-free high-density polyurethane foam that delivers exceptional thermal efficiency. This environmentally responsible insulation maintains consistent milk temperatures while minimizing compressor runtime and reducing electricity consumption by up to 40% compared to conventionally insulated tanks.

Direct Expansion Cooling System

- Superior Cooling Technology

Saset horizontal tanks utilize direct expansion (DX) cooling technology, the most energy-efficient method available for milk refrigeration. In this system, the evaporator forms the outer jacket of the inner tank, surrounding the milk completely. This direct contact eliminates intermediate heat transfer steps, resulting in faster cooling times and lower energy consumption.

- Rapid Chilling Performance

The powerful cooling system achieves remarkable performance specifications:

- Cools milk from body temperature (32°C-38°C) to safe storage temperature (4°C) in less than 3 hours

- Operates efficiently in ambient temperatures up to 35°C, ideal for Kenya’s tropical climate

- Uses R-404A refrigerant charged at optimized levels for maximum efficiency

- Provides frost-free cooling even with minimum milk quantities in the tank

- Maintains consistent temperatures during milk storage periods

- Professional-Grade Components

Each cooling system features a scroll compressor mounted on a robust monolithic chassis alongside the tank. Scroll compressors are renowned for their reliability, quiet operation, and superior energy efficiency compared to reciprocating designs. The integrated chassis design minimizes vibration and ensures stable operation throughout the tank’s operational life.

- Intelligent Mixing System

The integrated agitation system features a precision-engineered 28 RPM reducer coupled to stainless steel mixing blades. This carefully calibrated speed ensures gentle but thorough milk circulation, preventing cream separation and temperature stratification without damaging delicate milk fat globules or creating excessive foam.

The automated mixing system operates intelligently based on milk temperature. After reaching the target cooling temperature, the programmable controller cycles the mixer on and off at customizable intervals (typically 10 minutes on, 5 minutes off) to maintain uniform temperature with minimal energy consumption.

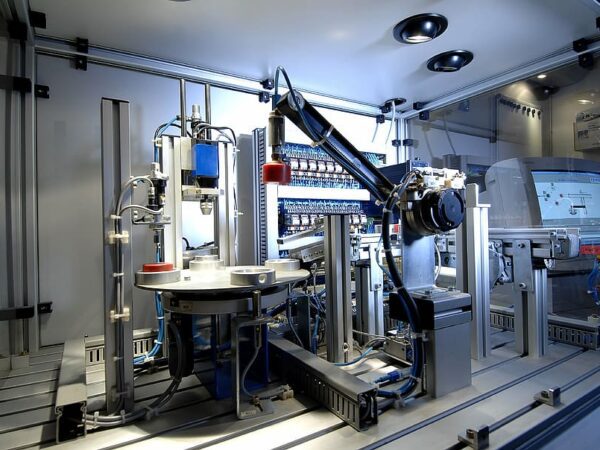

Advanced Electrical Control Systems

- User-Friendly Touch Screen Interface

The ergonomically designed control panel features an intuitive touch screen interface that makes tank operation simple even for operators with minimal technical training. The special design provides at-a-glance status information and easy access to all control functions.

- Comprehensive Monitoring and Control

The sophisticated electronic control system includes:

- Digital Thermometer: Provides real-time temperature monitoring with precision accuracy

- Electronic Control Card: Manages all cooling and mixing operations automatically

- Automated Temperature Management: Maintains milk within specified temperature ranges without manual intervention

- Phase Protection Relay: Safeguards the compressor and electrical components from voltage irregularities

- IP65 Protection Rating: Ensures electrical components withstand the humid, washdown environment of dairy facilities

- Reliable Power Management

Designed for Kenya’s 380V 50/60Hz power supply, the electrical system incorporates multiple safety features that protect your investment from power-related damage while ensuring uninterrupted operation.

- Digital Level Indicator System

The precision digital level monitoring system provides exceptional accuracy with measurement precision within 0.2% (±0-2‰). The system displays milk quantity in both kilograms and liters on the main control panel, allowing operators to track inventory precisely. This accurate volume measurement assists with production planning, quality documentation, and financial record-keeping.

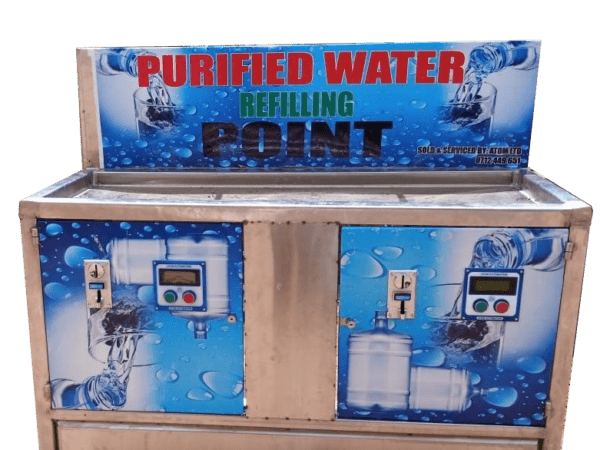

Automated CIP Cleaning System

- Clean-in-Place Technology

The integrated CIP (Clean-in-Place) system revolutionizes tank sanitation by automating the entire cleaning process. This sophisticated system cleans all interior surfaces, pipes, fittings, and associated equipment without requiring disassembly, dramatically reducing labor requirements and ensuring consistent cleaning quality.

Key CIP Features

- One-Button Operation: Initiate complete cleaning cycles with a single touch

- Mechanical Residue Removal: Powerful spray action removes milk residues from all internal circuits

- Low Chemical Consumption: Optimized detergent dosing minimizes operating costs

- Easy Detergent Management: User-friendly cabinet and precision dosing pump simplify chemical handling

- Safety Interlocks: Advanced security systems prevent water contamination of milk product

Practical Design Features

- Optimized Product Flow

The tank design incorporates thoughtful features that streamline daily operations:

-

- DN50 Male Butterfly Valves: Large product outlet with reliable butterfly valve design ensures quick, complete discharge

- 90mm Spring-Covered Inlet: Generous inlet diameter accommodates high milk flow rates during filling

- 200mm Manhole: Wide access opening with 100mm inlet facilitates thorough inspection and manual cleaning when needed

- Zero-Residue Drainage: Specially contoured bottom ensures complete tank emptying without manual intervention

- Adaptable Installation

Adjustable foot bolts on all support legs accommodate uneven floor surfaces, ensuring stable tank positioning without costly floor modifications. The free-standing design requires no wall mounting or special structural support.

- Universal Compatibility

Saset horizontal milk cooling tanks integrate seamlessly with any milking system, whether you operate bucket milking, pipeline systems, or automated parlor equipment. The versatile design accommodates various farm configurations and scales easily as your operation grows.

Available Options and Accessories

Customize your tank with professional-grade options:

- Automated CIP Washing System: Complete turnkey cleaning automation

- Digital Weighbridge Integration: Enhanced inventory management and quality documentation

- Milk Transfer Pump: Efficient product movement for processing or transportation

- Milk Watch Meter: Additional monitoring and quality assurance capabilities

- Professional Installation and Support

While transportation, insurance, electrical installation, and commissioning are arranged separately to provide flexibility, Saset’s technical team ensures proper setup and operator training. Standard production lead time is approximately 21 days from order confirmation, allowing for precise customization to your specifications.

Why Choose Saset Horizontal Milk Cooling Tanks?

For dairy operations that cannot compromise on milk quality, operational reliability, or long-term value, Saset horizontal milk cooling tanks deliver proven performance backed by local manufacturing expertise and comprehensive support. The combination of premium materials, advanced technology, intelligent automation, and energy-efficient design makes these tanks the preferred choice for Kenya’s most successful dairy enterprises.

Invest in equipment engineered to protect your milk quality, reduce operating costs, and deliver decades of dependable service. Contact Saset today to discuss your specific cooling requirements and discover how our horizontal milk cooling tanks can elevate your dairy operation’s performance and profitability.

Order a Saset Horizontal Milk Cooling Tank Today

Are you in the market for a high quality milk chiller? Saset is the leading manufacturer of top quality milk cooling tanks in Kenya. If you would like to invest in a milk cooling unit that serves you for a long time with peace of mind then no need to look further. Get in touch with us to place your order. Our expert technicians will manufacturer a milk chiller that meets your needs and to your specifications.

Contact us via any of the means below:

- Call us: You can call us at +254 727 38 48 26 or +254 101 74 74 47 and speak to one of our friendly and helpful staff. They will guide you through the ordering process and answer any questions you may have.

- Use WhatsApp: You can also use WhatsApp to send us a message at +254 727 38 48 26 or +254 101 74 74 47. You can send us your name, location, and the product you want to order. We will reply to you as soon as possible and confirm your order.

- Send an email: You can also send us an email at info@saset.co.ke with your name, location, and the product you want to order. We will reply to you within 24 hours and confirm your order.

- Use the contact form: You can also use the contact form on our contact us page to place your order. You just need to fill in your name, email, phone number, location, and the product you want to order. We will get back to you shortly and confirm your order.

You can also search for us on Google or visit our office/showroom in Ruiru, Kimbo, Thika Road, at the Toll Station bus stop. We are next to the Rubis Petrol station. We look forward to hearing from you and serving you with our quality products and services.